Ammonia Production Process Pdf

Radically new catalysts should be discovered to enable sustainable ammonia synthesis processes that can operate at much lower temperatures to relax the demand for high pressure. Ammonia use does present challenges.

Report an electrocatalytic rate for ammonia production of 556 mol g cat 1 h 1 for 100 h which even outperforms the Haber-Bosch process.

. It is interesting to compare this energy consumption to the catalysts from Table 1 especially the strained Ru nanoclusters catalyst as Yu et al. The ammonia plant of the Ammonia-Urea Ammonium Nitrate-Melamine AUM complex is the newest addition to the ammonia manufacturing plants. Methods that fix atmospheric nitrogen to ammonia under mild conditions could offer a more environmentally benign alternative to the HaberBosch process.

This page was last edited on 1 July 2022. The Next Step includes a detailed process flow diagram. Ammonia production depends on plentiful supplies of energy.

However adoption of ammonia as a hydrogen source especially for transportable devices and automobiles has been limited largely because of the absence of an efficient process for decomposing ammonia to hydrogen and nitrogen 1618 27Overcoming this issue will. Here are some NDSU Extension publications that can help you and your family during the COVID-19 pandemic. Ammonia is a compound of nitrogen and hydrogen with the formula NH 3A stable binary hydride and the simplest pnictogen hydride ammonia is a colourless gas with a distinct pungent smell.

The most commonly utilized ammonia production method is the Haber. The PCS 04 PLNL CNC N2000 plants use the Kellogg Advanced Ammonia Process. Lawrence Berkeley National Laboratory Scroll down to page 39 of 40 PDF pages for a list of the ammonia plants in the United States Ammonia.

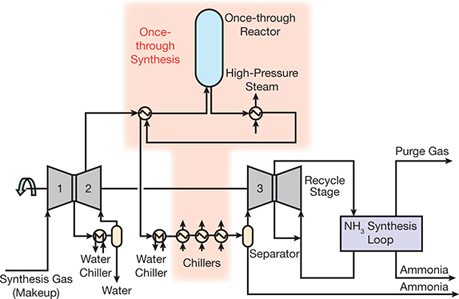

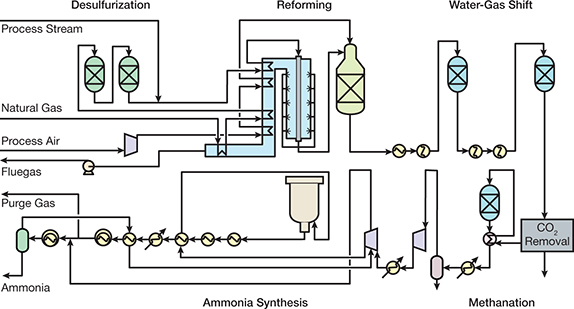

Climate Action - Technologies to reduce. Ammonia synthesis via the high-temperature and -pressure HaberBosch HB process at large centralized facilities has a significant contribution to global CO 2 emissions. Ammonia production process plant flow sheet in brief with three controls.

Biologically it is a common nitrogenous waste particularly among aquatic organisms and it contributes significantly to the nutritional needs of terrestrial organisms by serving as a. The future of a carbon-free society relies on the alignment of the intermittent production of renewable energy with our continuous and increasing energy demands. The global ammonia market size was USD 6701 billion in 2020.

Decarbonisation options mainly target the production of hydrogen either by integrating carbon capture and storage or through the production of hydrogen via water electrolysis using sustainable electricity. CO2 is widely used in food production and the move by CF is expected. 6 For the production of 1 kg ammonia the strained Ru.

Ammonia production currently accounts for around 18 of global carbon dioxide emissions. The lowest ammonia production rate could reach 72 10 9 mol s 1 cm 2 when Ag-Pd was used as electrodes and the cathode and anode were fed with dry nitrogen and wet hydrogen respectively. The hydrogen is then used to feed an ammonia synthesis process to produce ammonia.

Production of carbon dioxide a by-product of the ammonia production process will cease until the ammonia plant is restarted. The impact of COVID-19 has been unprecedented and staggering with NH3 witnessing a negative demand shock across all regions amid the pandemic. Its production capacity is approximately 650000 MT per annum and started production in April 2009.

Now a Ru-loaded electride Ca24Al28O64. Listen to Audio Version. Long-term energy storage in molecules with high energy content and density such as ammonia can act as a buffer versus short-term storage eg.

Based on our analysis the global market exhibited a decline of 168 in 2020 as compared to. Due to the important role of ammonia as a fertilizer in the agricultural industry and its promising prospects as an energy carrier many studies have recently attempted to find the most environmentally benign energy efficient and economically viable production process for ammonia synthesis. Yara is investigating producing renewable hydrogen to feed its ammonia production process which will reduce emissions produced by the facility.

The electrode involves two electrochemical reactions at the anode and cathode respectively. The table below shows the. The Yara Pilbara pilot plant will make 30000 tons of green ammonia that would otherwise be made with fossil fuels.

As mentioned hydrogen produced from ammonia is used in fuel cells engines and turbines.

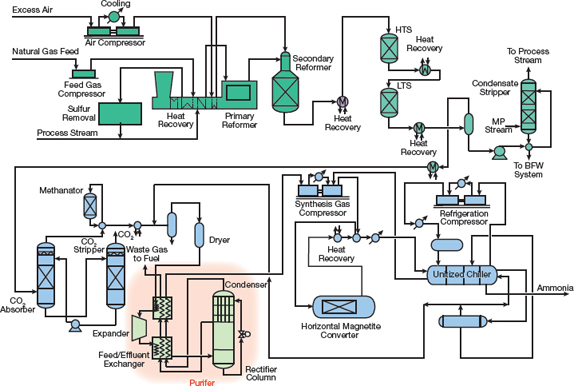

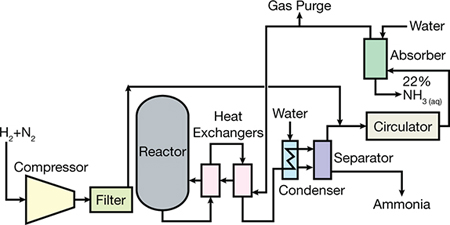

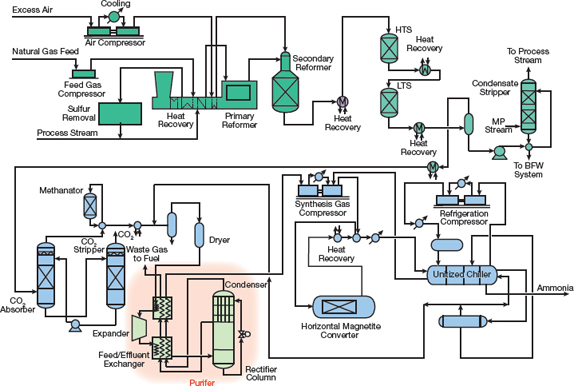

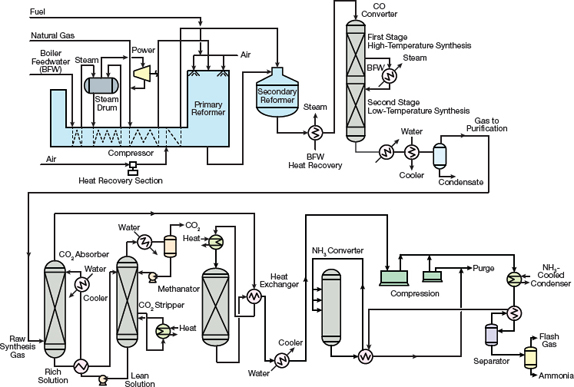

Ammonia Industrial Efficiency Technology Measures

Introduction To Ammonia Production Aiche

Introduction To Ammonia Production Aiche

Introduction To Ammonia Production Aiche

Comments

Post a Comment